Rival Worx

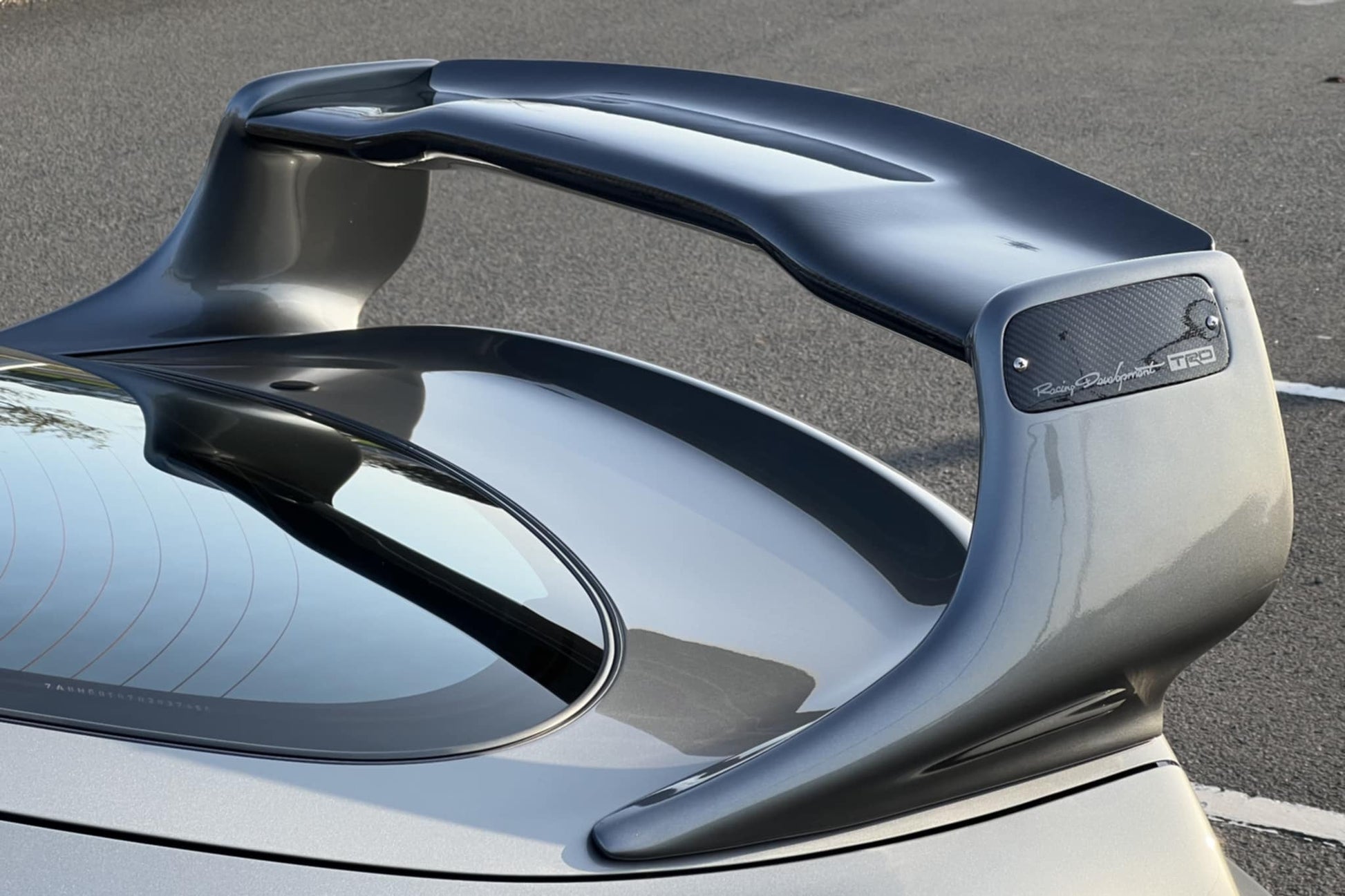

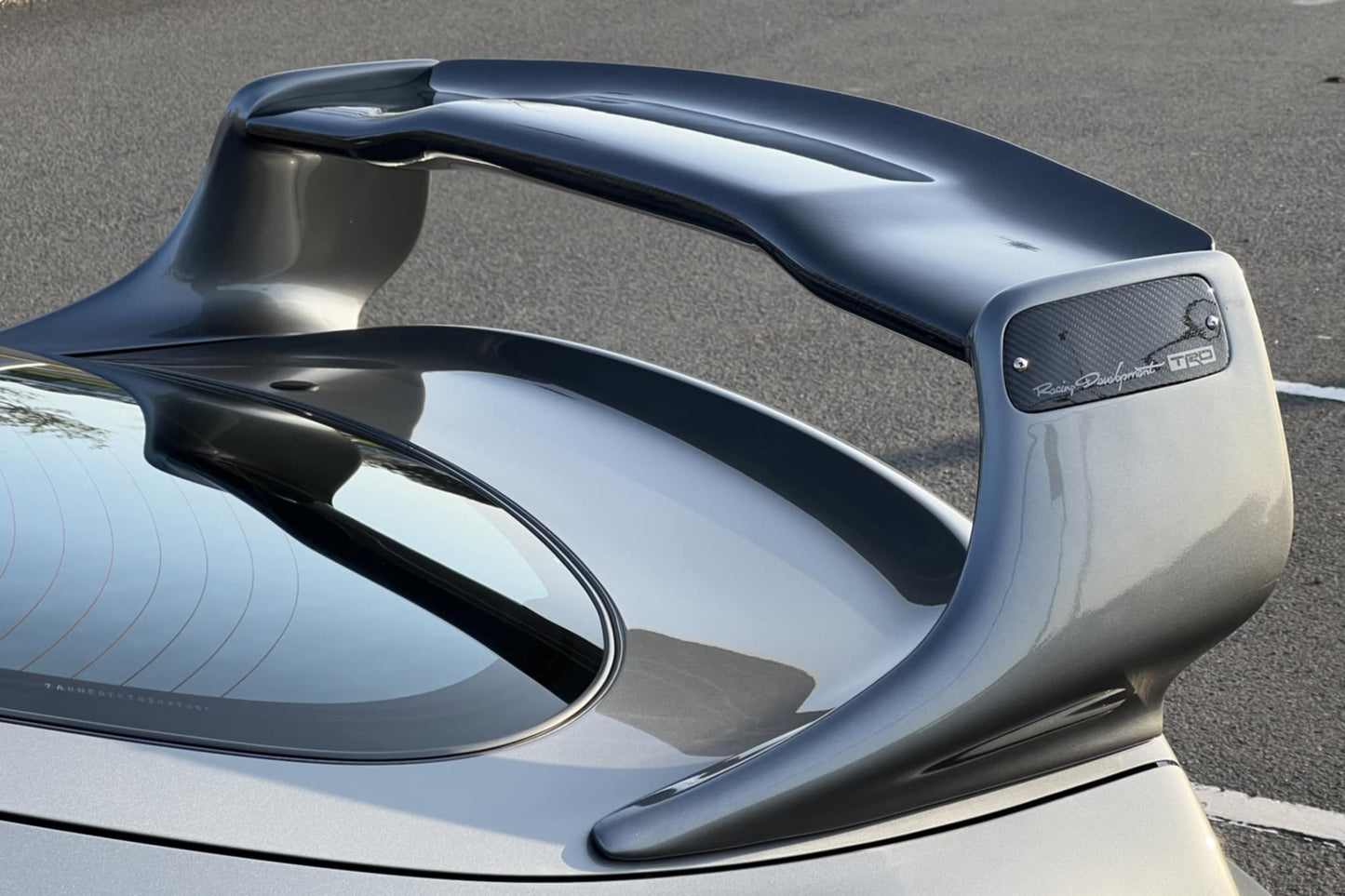

TRD 'Charge' Style Spoiler

Carbon Collections

Toyota Mk4 Supra Dash Panel 5-piece Kit

Carbon Fibre Toyota Supra Cooling Panel

More Than Just Carbon Fiber

-

OUR GOAL

Our goal is to provide not just a product but an experience, each step is taken with as much input from you as possible, and every decision made is not made without your input.

-

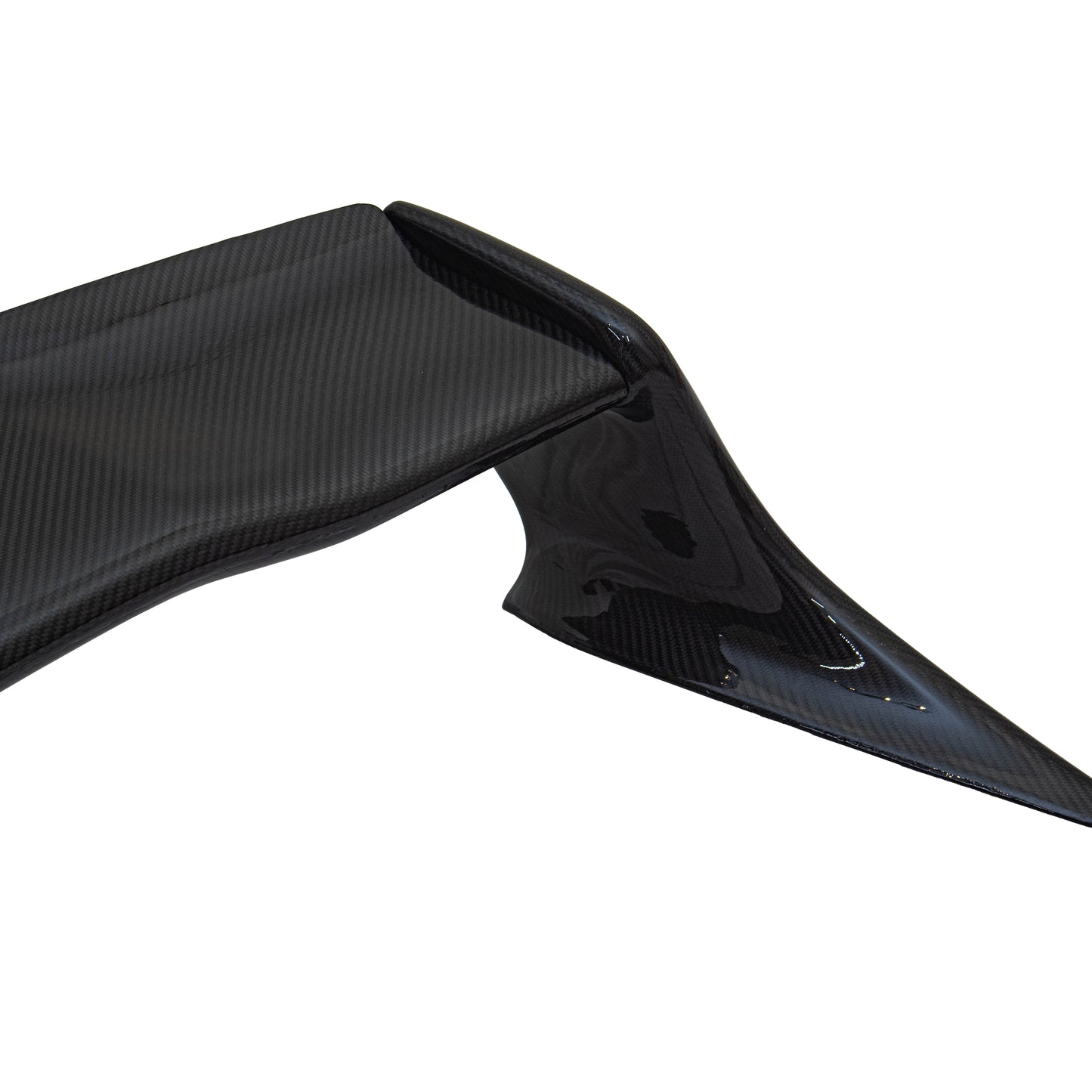

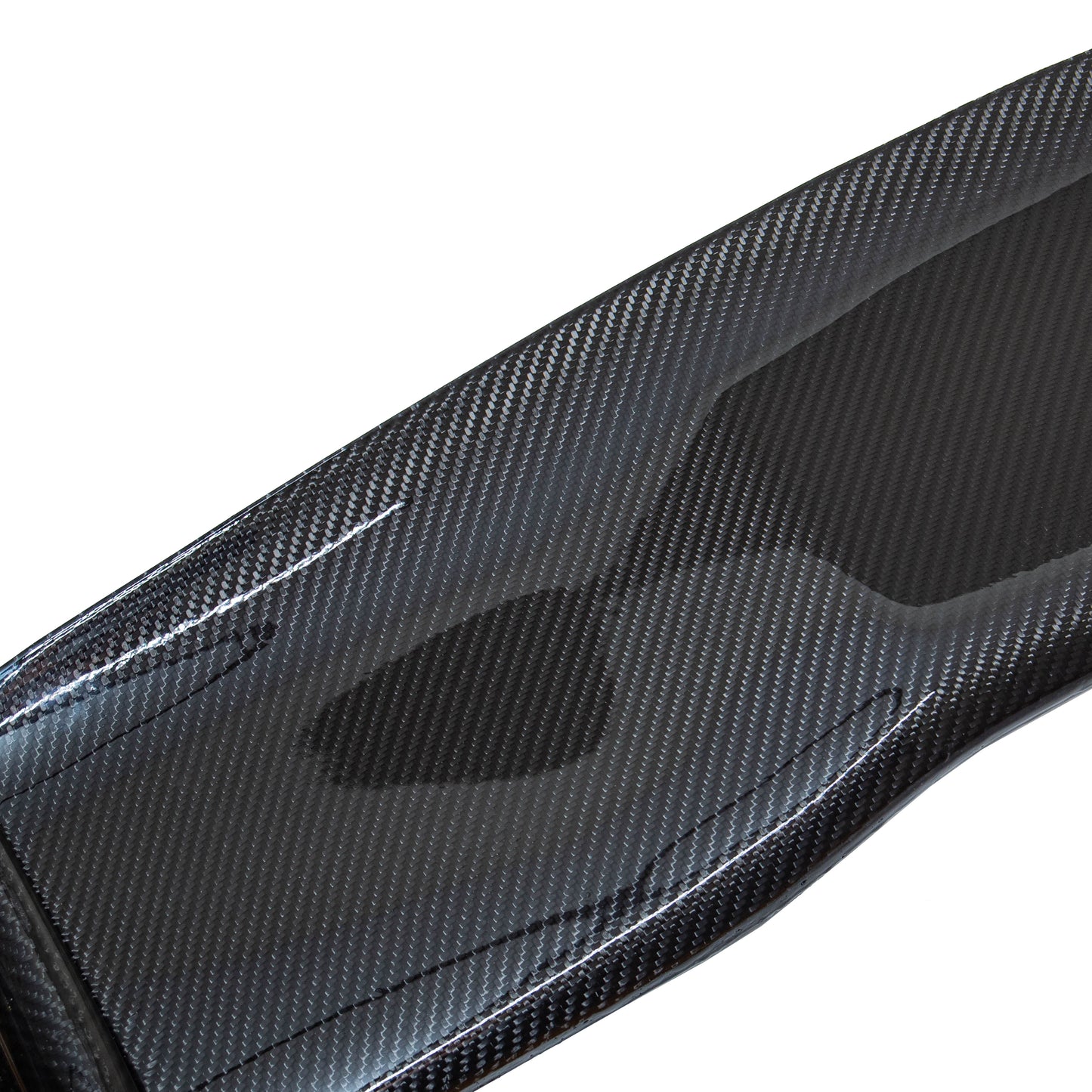

OUR CARBON

Carbon fibre products are only ever as good as the moulds used. Here at Rival Worx, we pride ourselves on making our own moulds and using only the best materials the market has to offer. We use 220 gsm 2x2 twill 3k which provides the best finish while not compromising on weight, we also offer a variety of carbon finishes. With the help of prepreg carbon fibre and infusion systems, we manage to create products that can compete with big-name manufacturers as they use the same fibre in the manufacturing of their supercars.

-

OUR PROCESS

After the initial consultation, where we work with you to determine the exact product specifications, we will take a 25% non-refundable deposit and work can start. The time this takes can vary from product to product; it should take 2 weeks dependent on specifications and stock. We use two types of processes. For bigger projects we use infusion (wet carbon fibre), while the carbon fibre is weaved an epoxy is applied to the surface and with high amounts of pressure and vacuum, the resin is pushed through the fibres until the consistency of resin throughout the fibres is measurably accurate, the structure is then cured and tested for quality. And prepreg common term for fabric reinforcement that has been pre-impregnated with a resin system. The resin system is typically an epoxy and already includes the proper curing agent. As a result, it's ready to lay into a mould without the addition of resin or the steps required of a typical hand lay-up. Only the best quality products reach the customer.